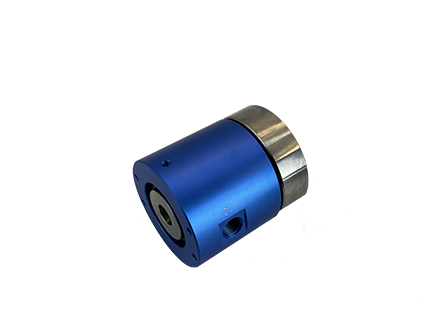

A anneau de glissement rotatifÉgalement connu sous le nom de connecteur rotatif électrique ou connecteur rotatif, il s'agit d'un composant électrique essentiel conçu pour assurer une transmission continue de puissance et de signaux entre les parties tournantes et fixes de l'appareil. Généralement installé au centre d'une machine tournante, il se compose de deux composants principaux:

A anneau de glissement rotatifÉgalement connu sous le nom de connecteur rotatif électrique ou connecteur rotatif, il s'agit d'un composant électrique essentiel conçu pour assurer une transmission continue de puissance et de signaux entre les parties tournantes et fixes de l'appareil. Généralement installé au centre d'une machine tournante, il se compose de deux composants principaux:

Le rotor, qui est relié à la structure rotative et se déplace avec elle.

Le stator, qui est fixé à la structure fixe et fournit de la puissance ou des données.

Grâce au mécanisme de la bague coulissante, une transmission précise de la puissance, du signal de données, de l'image et même de la puissance est réalisée entre deux entités en rotation relative.

Caractéristiques principales de Anneaux de glissement rotatifs

360 degrés de rotation illimitée : le anneau de glissement rotatif Prend en charge une rotation continue de plus de 360 degrés pour fournir une transmission fiable de puissance et de signal à divers appareils rotatifs.

Transmission de haute précision: Fabriquée en utilisant des techniques de précision avancées et des matériaux de haute qualité, elle assure une durabilité et des performances stables lors de rotations à grande vitesse, en maintenant des données précises et un transfert de puissance.

Intégration multifonctionnelle: Ces anneaux de glissement peuvent intégrer la transmission de puissance, de données, de signal et d'image dans une seule unité, répondant aux besoins de machines complexes.

Longue durée de vie: Avec des matériaux résistants à l'usure et une conception optimisée, les anneaux de glissement rotatifs sont construits pour un fonctionnement durable et stable dans des conditions difficiles.

Structure compacte: La conception compacte minimise l'utilisation d'espace, rendant l'installation et l'entretien plus simples.

Paramètres du produit

Vie professionnelle | Se référer au tableau de sélection de la qualité du produit | Voltage nominale | 0 - 440vacndc |

Vitesse de rotation nominale | Se référer au tableau de sélection de la qualité du produit | Résistance à l'isolation | <500mq> |

Température de travail | -30°C à 80°C | Spécifications du fil | AWG17#/AWG22#Teflon revêtu d'argent |

Humidité de travail | 0 ~ 85% RXH | Longueur du fil | Longueur standard 250mm |

Matériel de contact | Se référer au tableau de sélection de la qualité du produit | Résistance à l'isolation | 500VAC@50XHz et 6S |

Matériau du boîtier | alliage aluminium | Valeur de changement de résistance dynamique | <0.010<> |

Rotation torque | 0.05N.m+0.02N.m/6Flow passage | Protection level | IP51 |

Functions of Anneaux de glissement rotatifs

Power Transmission: Rotary slip rings deliver stable electrical power to rotating devices, ensuring uninterrupted operation throughout their movement.

Signal Transmission: They enable the transmission of data, communication signals, and images, making them essential for control and monitoring systems.

Power and Signal Integration: In certain specialized applications, anneau de glissement rotatifs also facilitate the transmission of power (e.g., hydraulic or pneumatic power), in addition to electrical signals.

Applications of Anneaux de glissement rotatifs

Industrial Machinery: In applications such as industrial robots and CNC machines, anneau de glissement rotatifs transmit power and data signals, ensuring precise control and stable operations.

Aerospace: Rotary slip rings are used in rotating components of aerospace systems, such as radar antennas and gyroscopes, facilitating continuous power and signal flow.

Surveillance and Security: For security camera systems, especially those with pan-tilt-zoom (PTZ) capabilities, anneau de glissement rotatifs provide stable transmission of video signals and power.

Medical Devices: In medical equipment like CT scanners and MRI machines, anneau de glissement rotatifs ensure the continuous transfer of images and data, essential for accurate diagnostics.

Military Equipment: Used in military radar, communication systems, and other equipment, anneau de glissement rotatifs play a critical role in signal and power transmission for mission-critical operations.

Maintenance and Care

Regular Inspections: Conduct regular checks on the slip ring, including visual inspections, wiring integrity, and insulation resistance, to ensure optimal performance.

Cleaning: Keep the slip ring surface free from dust and dirt using a clean cloth or brush, preventing interference with conductivity and rotation.

Lubrication: Apply a suitable lubricant to the rotating components to reduce friction and wear, extending the lifespan of the slip ring.

Avoid Overload: Ensure the slip ring operates within its rated current and voltage specifications to prevent overheating and damage.

Proper Installation: Follow installation instructions closely to avoid miswiring or improper fitting, which could cause malfunction or failure.

Important Considerations

Operating Environment: Rotary slip rings should be used in dry, dust-free, and non-corrosive environments to protect the internal components.

Temperature Range: Ensure the slip ring operates within the specified temperature range to avoid performance degradation or failure.

Water and Dust Protection: For applications requiring waterproofing or dustproofing, choose slip rings with appropriate protection ratings to maintain functionality in challenging environments.

Electromagnetic Compatibility (EMC): Pay attention to electromagnetic interference (EMI) issues when integrating anneau de glissement rotatifs with other electronic systems to prevent signal disruption.

Storage Conditions: If storing a anneau de glissement rotatif for an extended period, keep it in a dry, ventilated space free from corrosive gases to prevent moisture or corrosion damage.

Conclusion

Anneaux de glissement rotatifs, also known as electrical rotary unions or rotary connectors, are vital components for industries requiring seamless power and signal transmission between rotating and stationary parts. By maintaining regular checks and following operational and environmental guidelines, these devices ensure high-performance and longevity, making them indisp

A

A